About us

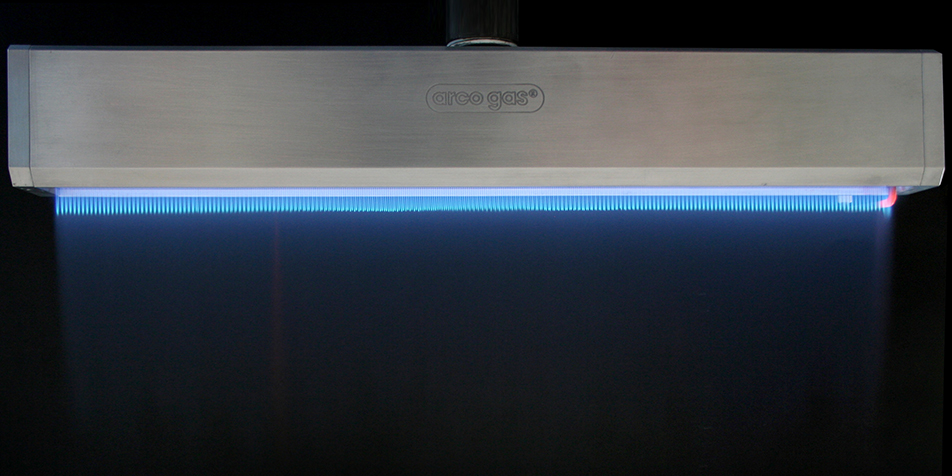

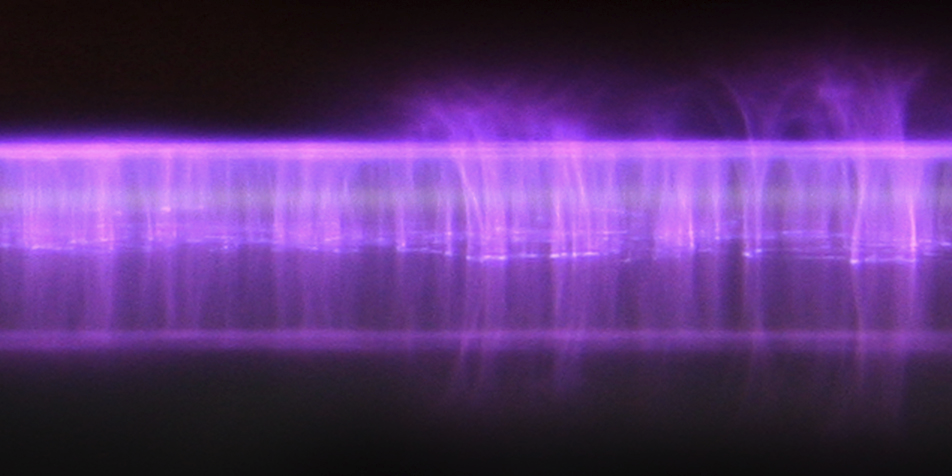

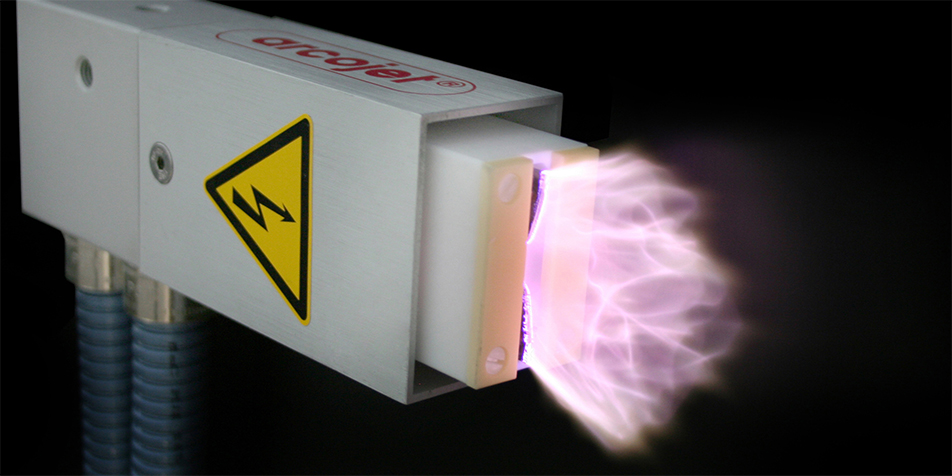

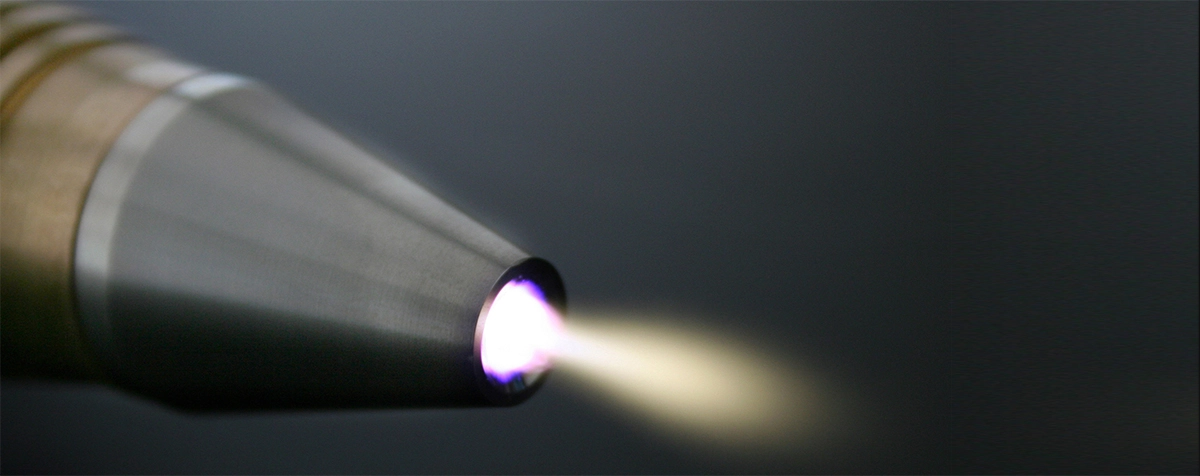

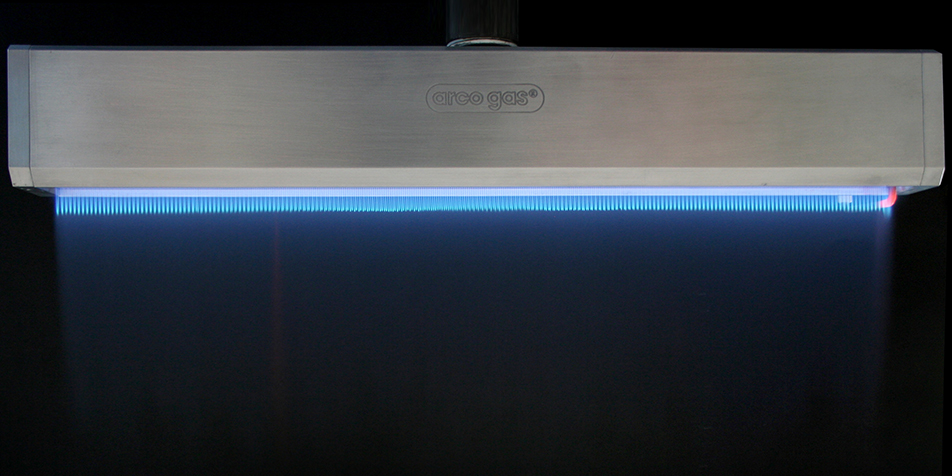

With almost 50 years of experience, Arcotec GmbH is a successful manufacturer of all three methods of physical pre-treatment under atmospheric pressure (corona, plasma, flame). The more than 25,000 Arcotec treatment units in use world-wide are an attribute to our continued high quality and our unique know-how in the field of surface pre-treatment.